HOT WORK STEELS (DIN 1.2714, 2343, 2344)

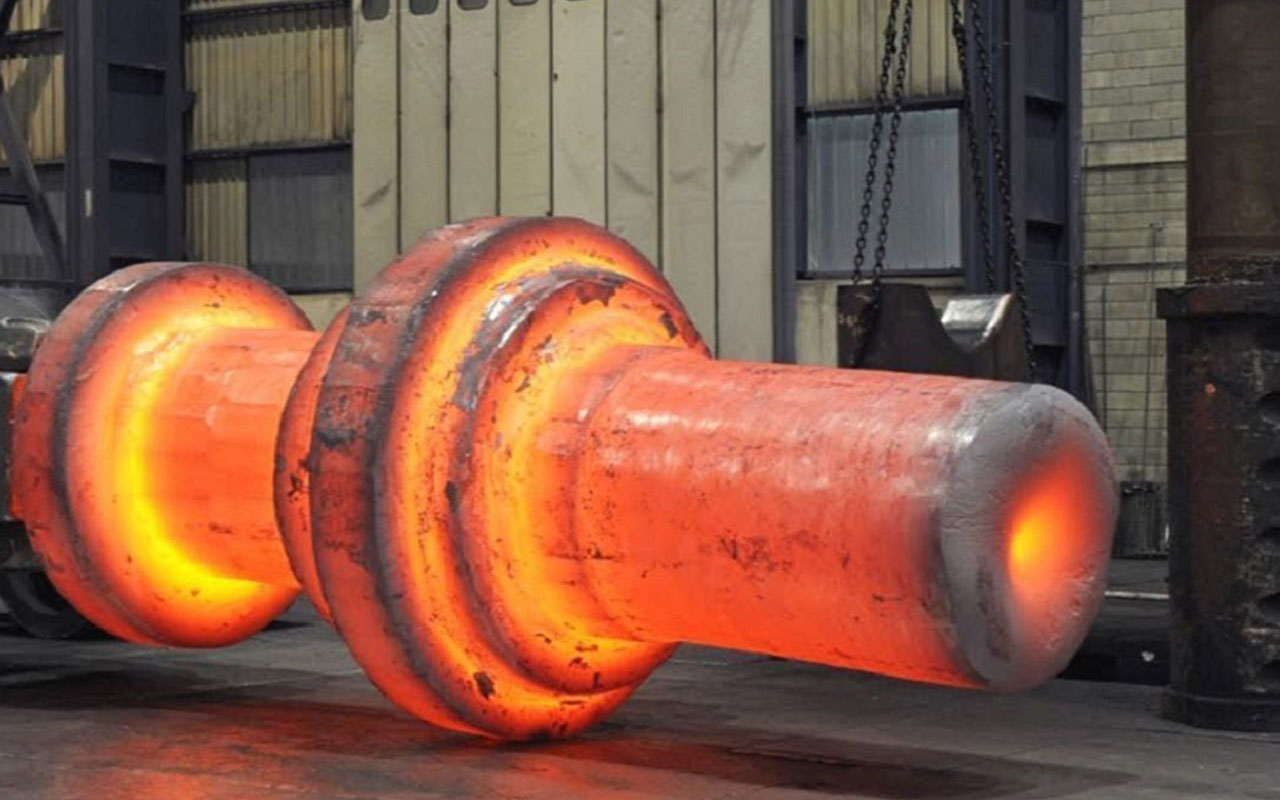

These steels work with heat. They are recognized for great wear resistance, heat conductivity, hardness and robustness at increased temperatures. These steels have better features for use due to decreased Sulphur level.

DIN 1.2714

DIN 1.2714 is highly recommendable for Close Die Forging due to its characteristics of high ware-resistance, extra toughness, high hardness achieved with Cr-Ni-Mo-V high graded alloys.

Din 1.2343

Din 1.2343 is an all-inclusive hot work tool steel with hot rigidity and durability. Good thermal conductivity and invulnerability to hot cracking can be water-cooled to a constrained degree.

Utilized for ejector pins, apparatus holders and shrink fit chucks.

DIN 1.2344

DIN 1.2344 is a tool steel grade standardized for hot working. The main feature of this grade is the combination of alloyed elements of chromium, molybdenum and vanadium, Cr-Mo-V, which provides a high wear resistance to thermal shock. It is well known as for its great strength, and heat resistance.

Application:

Dies for Drop forgings , Aluminum / low pressure Die Casting , Extrusion , Containers & liner , Punches , Plugs , Holder, Injection moulds Etcs.

Chemical Composition

C | 0.35-0.42 |

Si | 0.90-1.20 |

Mn | 0.30-0.50 |

P | <0.030 |

S | <.004 |

Cr | 4.90-5.40 |

Mo | 1.20-1.40 |

V | 0.90-1.10 |